KGSA 2021 Show Commemorative Knife

By Stuart Smith

Under the sweltering sun, in front of a roaring forge, I hammered my steel. Not ideal conditions for a demonstration considering the bladesmiths ideal environment is dark and private. But such was my experience during the Knifemakers Guild of South Africa show this year.

Each year I perform a simple forging demonstration to help illustrate a small portion of the blade smithing process in birthing a knife. This usually begins at six in the morning and me rushing around the house because I woke up late and there is no time to pack my kit in the car in time for me to leave. I haul the 75kg anvil and its edge ridden stand, inevitably bashing me somewhere about my person, into the car. Followed by the forge itself, a gift from a former student, now full-time maker and Journeyman Smith, Neels van den Berg. It’s a useful and portable tool, that always stains my clothes just before the show.

Workshop in tow I dash off to the Kyalami, the new venue, in great trepidation. What will it be like? Do the people still remember us? 2020 was the year that never was, no movies, no parties and… no show. But here we are, ready to start again, as am I, filled with excitement and dread I haul butt to the venue. Inevitably I must navigate security guards to get my car close to my assigned space. To my consternation I see it is an open area, full sun. Oh well, for queen and country.

Anvil and forge unloaded, along with the required tools and a hastily chosen piece of steel, not ideally suited for a forging demo, are all unloaded and set up, awaiting my arrival at midday. That is until I am told to move it all ten meters to the left. I take my stock of knives inside to my table and set up for the arrival of customers and collectors. Seeing old friends for the first time in a while is both wonderful and exhausting. The solitary life of social distancing and isolation has left little energy for the experience of … people.

My time approaches after the usual patter and finagling of sales. The forge awaits! I arrive to the eager eyes of my audience, waiting to see what all the fuss is about. I ask for a light because, I am me, and running late, excluded the packing of my own damn lighter. I fire up and the familiar roar of the forge fills the air. I know this sound. It is part of an orchestra that I am about to conduct. My hammer is my baton, my anvil the percussion and the forge my woodwinds.

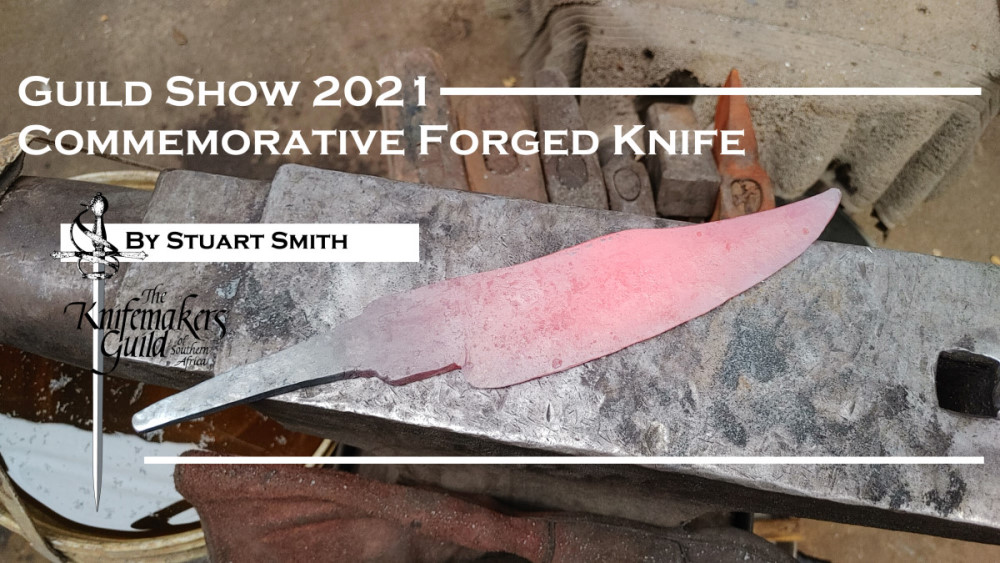

I take my awkwardly shaped piece of steel, which I must expertly forge into a convincing knife. In reality I would have used some of my more modern tools to make it a more convenient form on order to forge into a knife. But, woe to me, I only have my hammer and anvil. So gritting my teeth I forge ahead. The sun beats down on me, bright and unrelenting, much like my audience. I hammer confidently, but inside I am muttering about the stupid piece of steel I chose. Nevertheless, I coax the rough shape of a knife out of it. Not my finest work yet demonstrates some of the basic skills it takes to forge a blade.

The steel itself was very special, though inconveniently shaped. It involves an adventure with Neels and me, driving in his bakkie down to Natal to visit the Okapi factory. My good friend Stephan Diedericks was factory manager at the time and had contacted us regarding some excess steel they had on the stock floor. Long 7mm sheets of 1070 (0.7% high carbon steel) had been sitting there for years rusting. He sold it off to us at a steal. What was a 7hr drive down turned into a 12 hr journey home as we almost pushed his bakkie, loaded with almost 2 tons of steel up Van Reenens pass.

The reward was some of the best steel I have ever used for knives. Something about it was different. We joke that it had matured, and I am sticking to that story. This obsequious piece of steel that I forged into a knife was made from that batch. And seeing the result after I finished the knife reminded me why I love it so much.

After the show I took the blade home and spent some time in the comfort of my own workshop and reforged it some more to an acceptable finish. After that the regular process of knifemaking ensued. I ground the blade and applied a clay coating so that it would take a Hamon (Japanese style temper line denoting the division between hard and soft steel) After polishing and etching I assembled a handle of bronze and finest Arizona desert iron wood. I am very happy with the result and proud to present to you the KGSA 2021 commemorative knife. The dedication will be engraved into the spine of the blade before it is delivered to the successful bidder. The knife will also be accompanied by a fine sheath made by my wife.

I thank you for joining me on this journey and hope you all bid to get a small piece of history. You will be able to bid on this knife on the Knifemakers Guild of South Africa facebook page from Monday 15th Nov to Wednesday 17th Nov. Please click on the link below that will take you there.

Click here to visit the Facebook page

Stuart Smith (JS)